Dispensing System

High Precision Dispenser

High Precision Dispenser

Introduction

The AD-100 is a high-precision, benchtop fluid dispensing control, for advanced applications of fluids that change viscosity. It will apply liquids to thick pastes by simply adjusting the air pressure gauge - with repeat deposits using the adjustable timer or controlled beads when the timer is switched off. An adjustable vacuum suck-back prevents any watery liquids from dripping. Experience a new level of accuracy, consistency, and process control when dispensing glue, epoxy, oil, grease, silicone, sealant, cyanoacrylate, solder paste, and other fluids. Supplied with syringe barrels but options for using other barrel sizes from 3cc to 55cc.

Features

- ※ Full electronic pressure regulation.

- ※ Underfill, Glob top, General dispensing applications.

- ※ Turns unit on and off. Illuminated to indicate “ON” position.

- ※ Adjust the intensity of the “suck back” vacuum applied to the dispensing circuit.

- ※ Foot switch, Activates the dispensing circuit.

Specification

|

Specification / Model |

AD-100 |

|

Timer Range |

0.01~9.999 Sec |

|

Air Output |

0~100 Psi |

|

Leak-proof Function |

Vacuum device |

|

Repeatability |

± 1% |

|

Cycle Initiate |

Foot pedal or finger switch |

|

Operation Condition |

10~40℃/20~80% |

|

Power(AC Input ) |

100~240 VAC, ±10%, 50/60Hz |

|

Power(DC Output ) |

DC24V |

|

Dimensions(W/D/H) |

185x195x80mm |

|

Weight |

1Kg |

Digital Pneumatic Dispenser

Digital Pneumatic Dispenser

Introduction

The AD-110 is a digital pneumatic dispenser with a dispensing time as low as 0.001 seconds. Bench top dispensing systems are for the controlled application of liquids and pastes. It contains a digital display with an adjustable air regulator and an adjustable timer. The vacuum sucks back to control drips and prevent oozing; and makes fast repeat shots or controlled beads of any liquid or paste at the press of a footswitch. Experience a new level of accuracy, consistency, and process control when dispensing glue, epoxy, oil, grease, silicone, sealant, cyanoacrylate, solder paste, and other fluids.

Features

- ※ Full electronic pressure regulation.

- ※ Underfill, Glob top, General dispensing applications.

- ※ Turns unit on and off. Illuminated to indicate “ON” position.

- ※ Adjust the intensity of the “suck back” vacuum applied to the dispensing circuit.

- ※ Foot switch, Activates the dispensing circuit.

Specification

|

Specification / Model |

AD-110 |

|

Timer Range |

0.001~99.99 Sec |

|

Air Output |

0~100 Psi |

|

Leak-proof Function |

Vacuum device |

|

Repeatability |

± 0.05% |

|

Cycle Initiate |

Foot pedal or finger switch |

|

Operation Condition |

10~40℃/20~80% |

|

Power(AC Input ) |

100~240 VAC, ±10%, 50/60Hz |

|

Power(DC Output ) |

DC 24V |

|

Dimensions(W/D/H) |

185x195x80mm |

|

Weight |

1Kg |

3-Axis Benchtop Robot

3-Axis Benchtop Robot

Introduction

The AREATAI 3-Axis Series automated fluid dispensing system is a benchtop robot that features a simple-to-use Teach Pendant, for quick setup and easy programming. Dispensing robots automate most of the fluid assembly processes, ensuring fast and repeatable deposits without mess, waste, or error. Making repeated dots, beads, arcs and circles of any fluid, adhesive, liquid, or paste. Available in four sizes, from 200 x 200 mm to 500 x 500 mm, the 3-Axis Series adapts to a wide range of working envelopes.

Features

- ※ Faster cycle and batch times.

- ※ 100 programs, 9,999 points memory per program compact flash card.

- ※ Teach Pendant program storage capabilities allows the dispense program to be easily transferred from

Robot to Robot. - ※ High speeds are achieved, reducing time spent manually applying adhesives and other many other fluids.

Specification

|

Specification / Model |

AD-232 |

AD-233 |

AD-235 |

|

Working area(X/Y/Z) |

200x200x100mm |

300x300x100mm |

500x500x100mm |

|

Maximum speed(XY/Z) |

800/300mm |

||

|

Repeatability |

± 0.01mm |

||

|

Tool payload |

6Kg |

||

|

Workpiece payload |

11Kg |

||

|

Memory capacity |

100 programs |

||

|

I/O Signals |

8 Inputs & 8 Outputs |

||

|

Input AC |

100~240 VAC, ±10%, 50/60Hz |

||

|

Dimensions |

650x650x900mm |

750x750x900mm |

850x850x900mm |

|

Weight |

40Kg |

50Kg |

60Kg |

4-Axis Benchtop Robot

4-Axis Benchtop Robot

Introduction

The AREATAI 4-Axis Series automated fluid dispensing system is a benchtop machine that features a simple-to-use Teach Pendant, for quick setup and easy programming. Dispensing machine automate most of the fluid assembly processes, ensuring fast and repeatable deposits without mess, waste, or error. Making repeated dots, beads, arcs and circles of any fluid, adhesive, liquid, or paste. Available in four sizes, from 200 x 200 mm to 500 x 500 mm, the 4-Axis Series adapts to a wide range of working envelopes.

Features

- ※ Faster cycle and batch times.

- ※ 100 programs, 9,999 points memory per program compact flash card.

- ※ Teach Pendant program storage capabilities allows the dispense program to be easily transferred from

Robot to Robot. - ※ High speeds are achieved, reducing time spent manually applying adhesives and other many other fluids.

Specification

|

Specification / Model |

AD-242 |

AD-243 |

AD-245 |

|

Working area(X/Y/Z/R) |

200x200x100mm /360゜ |

300x300x100mm /360゜ |

500x500x100mm /360゜ |

|

Maximum speed(XY/Z) |

800/300mm |

||

|

Repeatability |

± 0.01mm /0.2゚ |

||

|

Tool payload |

6Kg |

||

|

Workpiece payload |

11Kg |

||

|

Memory capacity |

100 programs |

||

|

I/O Signals |

8 Inputs & 8 Outputs |

||

|

Input AC |

100~240 VAC, ±10%, 50/60Hz |

||

|

Dimensions |

650x650x900mm |

750x750x900mm |

850x850x900mm |

|

Weight |

40Kg |

50Kg |

60Kg |

Two Component Dispenser

Two Component Dispenser

Introduction

The AREATAI two component dispensing system precisely mixes two-part materials that have low or medium viscosity, while the flow rate can be adjusted depending on the application. The two-component mixing equipment, includes two-part epoxy dispensers, sealant dispensers and ambient temperature adhesive dispensing equipment. The mixing is done inside the static mixer thus guarantees a homogeneous mix at the desired ratio. Such units are widely used to attach parts, casting of housings, gasketing, sealing or just pure mixing/filling.

Features

- ※ Easy-to-use, entry-level system.

- ※ Variable ratios from 1:1 to 24:1.

- ※ Multiple tube sizes to pinpoint specific target ratios and deliver ratio accuracy to ±1%.

- ※ Stainless Steel Parts for extended operational life and compatibility with the dosed product.

Specification

|

Specification / Model |

AD-330 |

AD-340 |

AD-350 |

|

Working area(X/Y/Z) |

300x300x100mm |

400x400x100mm |

500x500x100mm |

|

Shot size range |

0.2~100cc |

||

|

Dispensing accuracy |

± 2% |

||

|

Repeatability |

± 1% |

||

|

Typical Material |

Epoxy, Sealant, Adhesive, Silicone, Urethane |

||

|

Reservoir Capacity |

1.5 /2 /20 /40 Liter |

||

|

Ratio range |

1:1 up to 24:1 |

||

|

Power(AC Input ) |

100~240 VAC, ±10%, 50/60Hz |

||

|

Dimensions |

482x485x670mm |

650x650x900mm |

750x750x900mm |

|

Weight |

40Kg |

50Kg |

60Kg |

UV-LED Spot Curing

UV-LED Spot Curing

Introduction

The AD-410 high-intensity spot curing system features all the benefits of LED-curing technology in a smaller, more versatile unit. This system consists of a controller, a footswitch, and up to four LED heads. It's using LED curing light to cure adhesives on medical devices, electronics and other industrial and commercial applications. UV Spot Cure Systems can be equipped with rod lenses, single or multi-pole lightguides in various diameters and lengths for a variety of curing options.

Features

- ※ High performance head for easy operation.

- ※ One controller controls up to four LED heads for maximum application flexibility.

- ※ LED heads for 365, 385, 395or 405 nm wavelengths for better compatibility.

- ※ Instant on-off – no warm-up period and more energy efficient.

- ※ Operation without overheating and comfortable hand-held operating temperature.

Specification

|

Specification / Model |

AD-410 |

|

Wavelength |

365, 385, 395, 405nm |

|

Peak irradiance |

Up to 10,000mW/cm² |

|

LED timer |

0.1~999 Sec |

|

LED activation |

Footswitch or front panel |

|

Cooling |

Natural convection |

|

Lifetime |

LED Lamp/25,000 hr |

|

Power(AC Input ) |

100~240 VAC, ±10%, 50/60Hz |

|

Dimensions(W/D/H) |

80x140x125mm |

|

Weight |

940g |

|

Unit warranty |

1 year from purchase date |

UV-LED Flood Curing

UV-LED Flood Curing

Introduction

The AD-450 UV LED floodlight curing systems deliver homogeneous & powerful light for larger curing areas. Our UV LED floodlight curing system provides the highest intensity UV light for uniformly curing a large area. They can be used in small-volume production or be integrated into fully automated assembly lines. The UV LED flood curing lamp choice will differ according to insolation surface size, UV power/energy & controlling mode needed.

Features

- ※ High performance head for easy operation.

- ※ LED heads for 365, 385, 395, or 405 nm wavelengths for better compatibility.

- ※ Instant on-off – no warm-up period and more energy efficient.

- ※ Operation without overheating and comfortable hand-held operating temperature.

- ※ Individual exposure times and intensity settings available in 1% increments for each LED head allows for

maximum curing flexibility.

Specification

|

Specification / Model |

AD-450 |

|

Wavelength |

365, 385, 395, 405nm |

|

Peak irradiance |

Up to 2500mW/cm² |

|

Curing area |

100x100mm |

|

Lamp module |

Removable, irradiator built-in |

|

Intensity uniformity |

±10% (5% typ.) across entire part stage |

|

LED timer |

0.1~999 Sec |

|

LED activation |

Footswitch or front panel |

|

Cooling |

Natural convection |

|

Lifetime |

>25,000 hr |

|

Power(AC Input ) |

100~240 VAC, ±10%, 50/60Hz |

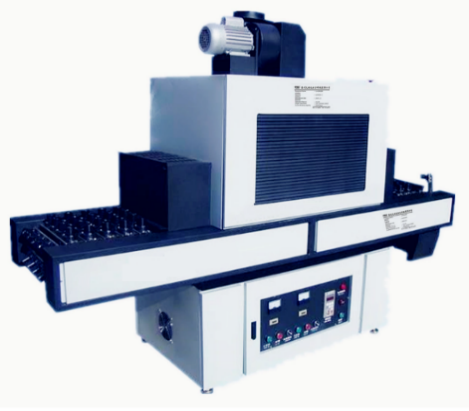

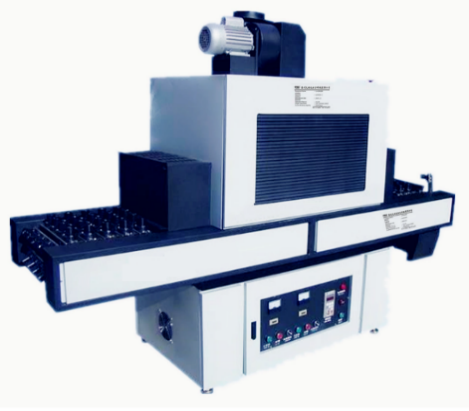

UV Conveyor Curing

UV Conveyor Curing

Introduction

The UV conveyor curing system is an air cooled table top conveyor belt UV LED curing system. Units offer floor standing or benchtop standard metal halide (longwave) or mercury (shortwave), bulbs, or LED arrays. The conveyor systems offer consistent, fast, and safe cures of UV and LED curable adhesives, coatings, and inks. The distance between the UV LED system and the conveyor is easily adjustable, along with the speed of the conveyor belt, and stable lamp intensity to provide light curing for repeatable processing and optimized throughput.

Features

- ※ Consistent UV curing, Complete UV shielding.

- ※ Easy to use – on/off, speed indicator, lamp on/off.

- ※ Integral cooling and vacuum hold-down.

- ※ Adaptable–easily adjustable lamp height, orientation, and belt speed.

Specification

|

Specification / Model |

AD-460 |

AD-480 |

|

Wavelength |

250nm~360nm |

320nm~380nm |

|

Peak Irradiance |

>50mW/cm² |

>150mW/cm² |

|

Lifetime |

>1500 hr |

|

|

Lamp power |

1000W / 2000W / 4000W |

|

|

Belt speed |

0~5M/min |

|

|

Lamp adjustment range |

20~210mm |

|

|

Maximum parts |

W250xH100mm |

|

|

Input AC |

100~240 VAC, ±10%, 50/60Hz |

|

|

Overall dimensions (without lamps) |

360x1200x420mm |

|

|

Weight |

45Kg |

|

PUR Dispensing System

PUR Dispensing System

Introduction

The AREATAI 30ml PUR dispensing system is designed to dispense dots or beads of PUR Hot Melt adhesive products packaged in 30 ml syringe barrels. A closed hot melt system protects PUR adhesive integrity and material characteristics. The system consists of a Controller, Dispense Head and Pre Heater. The system provides 3-Axis series and 4-Axis series, available in four sizes, from 200 x 200 mm to 500 x 500 mm.

Features

- ※ Easy-to-use, entry-level system.

- ※ Teach Pendant program storage capabilities allows the dispense program to be easily transferred from

Robot to Robot. - ※ Digital control for dispense head and pre heater temperature and dispense timer.

- ※ Integrated dispense time control, pressure control, and temperature control features into one system.

Specification

|

Specification / Model |

AD-532 |

AD-533 |

AD-535 |

|

Working area(X/Y/Z) |

200x200x100mm |

300x300x100mm |

500x500x100mm |

|

Shot size range |

0.2~30cc |

||

|

Dispensing accuracy |

± 2% |

||

|

Repeatability |

± 1% |

||

|

Operation temperature |

0~300℃ |

||

|

Typical Material |

Polyurethane |

||

|

Reservoir Capacity |

30ml |

||

|

Memory capacity |

100 programs |

||

|

Input AC |

100~240 VAC, ±10%, 50/60Hz |

||

|

Dimensions |

650x650x900mm |

750x750x900mm |

850x850x900mm |

|

Weight |

40Kg |

50Kg |

60Kg |

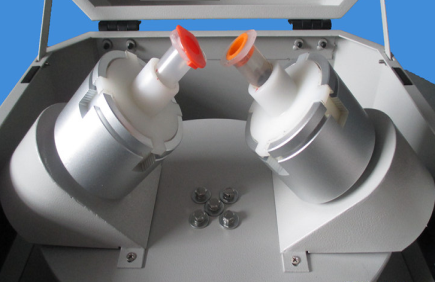

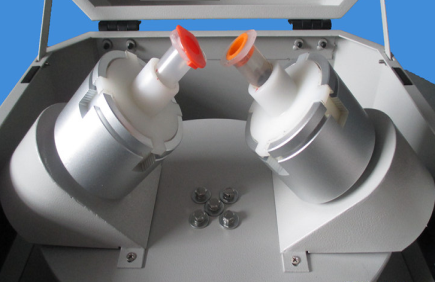

Planetary Centrifugal Mixer

Planetary Centrifugal Mixer

Introduction

AREATAI has introduced a planetary centrifugal mixer called AD-601. The product is the standard model with the help of this mixer, high-viscosity materials can be simultaneously mixed, dispersed, and dearated. The planetary centrifugal mixer choice will differ according to can be customized according to customer needs, and widely used in various products and industries. Applications include chemicals, cosmetics, medical/pharmaceutical, printing, soldering, drug preparation, conductive paste and sample testing.

Features

- ※ Memory function for simple pre-setting of mixing and deaeration condition.

- ※ Supports a broad range of materials, includes a wide range of adapters for various containers.

- ※ Disposable container eliminates the fuss of cleaning.

- ※ Heat-resistant, cold-insulated adapter supports numerous material properties.

Specification

|

Specification / Model |

AD-601 |

|

Operation Time Setting |

0~9.9min |

|

Defoaming Mode |

0~800rpm/min |

|

Mixing Mode |

0~400rpm/min |

|

Standard Container |

100 ml disposable container/ Customized |

|

Safety Mechanism |

Lid sensor, Speed sensor |

|

Rotation Angle |

45゜ |

|

Input AC |

100~240 VAC, ±10%, 50/60Hz |

|

Operation Condition |

10~45℃/40~80% |

|

Dimensions |

400x400x400mm |

|

Weight |

32Kg |